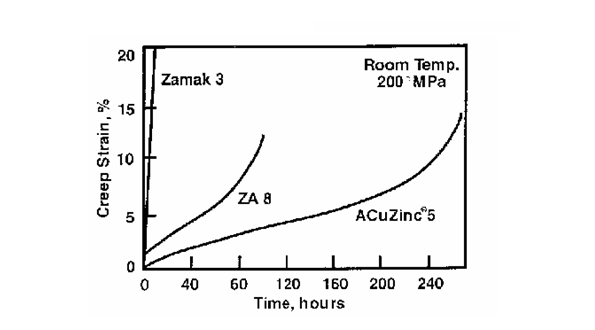

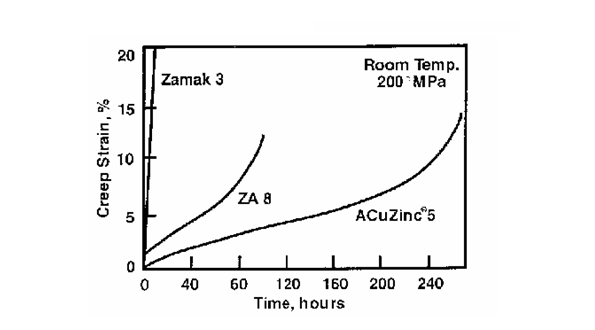

The newest of the Mazak family of zinc die-casting alloys. Acuzinc has been developed to give improvements in a variety of qualities needed in some die-cast parts. In die-cast condition Acuzinc has exhibited higher strenght, elongation (creep) hardness and ductility characteristics than those of Mazac 3 or 8. In addition to this it also gives lower wear rates and coefficients of friction. When compared with machined Brass, Acuzinc has showngood comparative hardness.

To achieve casting fluidity similar to other Mazak products, Acuzinc should be cast at 480 - 490°C. This may require the die-caster to adopt special melting practices. Details can be obtained from our Technical Support Staff.

| Mechanical Properties |

Gravity |

Die-cast |

| Tensile Strength (MPa) |

297 |

407 |

| Elongation (% in 51mm) |

4.5 |

0.4 |

| Hardness (HBN) |

100 - 115 |

105 - 125 |

| Impact Strength (Energy, Joules) |

15.6 |

|

| Fatigue Strength 106 cycles (MPa) |

155 |

84 |

| Physical properties |

|

| Density |

6.9 Kg/dm3 at 21°C |

| Casting temperature |

480 - 490°C |

| Specific heat capacity |

0.340 J/Kg/K at 20°C |

| Thermal expansion |

24.1 μm/m K |

| Thermal conductivity |

1.0570 J/s cm K at 20°C |

| Electrical conductivity |

26.9% IACS |

| Electrical resistance |

6.40 μ ohm cm at 20°C |

TYPICAL ANALYSIS

| Alloying elements |

|

| Aluminum |

2.8 - 3.3% |

| Copper |

5 - 6% |

| Magnesium |

0.025 - 0.05% |

| Impurities |

|

| Iron |

< 0.075% |

| Lead |

< 0.005% |

| Cadmium |

< 0.004% |

| Tin |

< 0.003% |